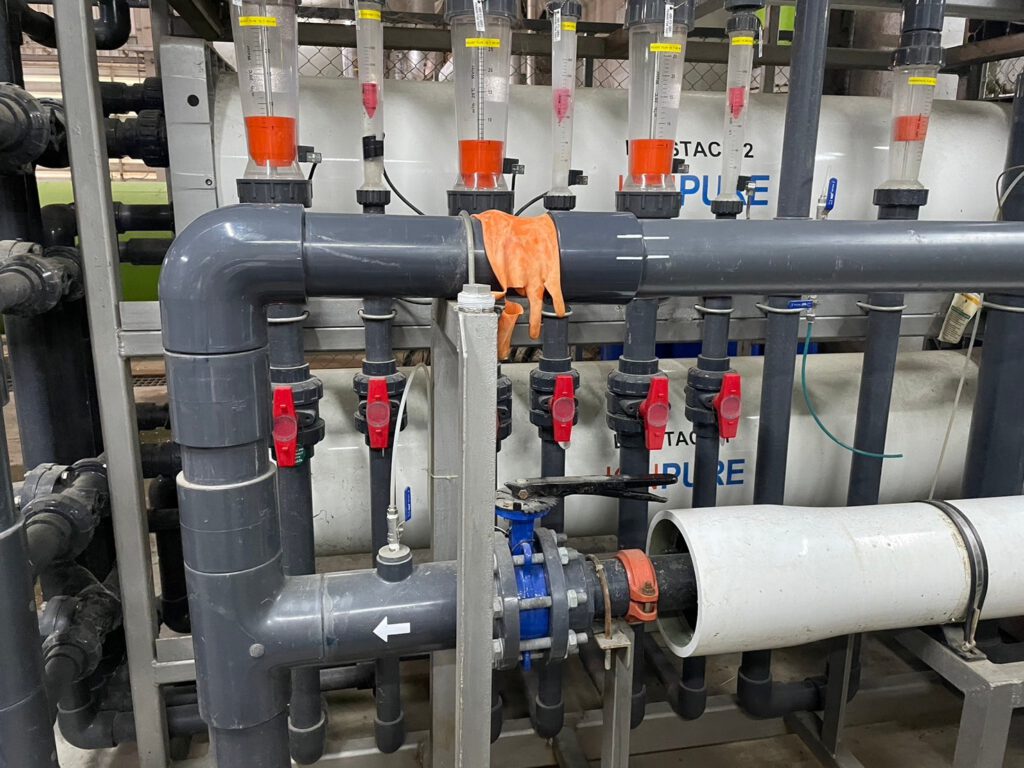

Electrodeionization (EDI) systems are vital for producing high-purity water in industries like power generation, pharmaceuticals, and electronics. However, like any advanced equipment, EDI stacks can experience failures that compromise performance and efficiency. Understanding the common reasons for EDI stack failures and the repair methods to address them can save significant costs and extend the system’s lifespan.

- Fouling and Scaling

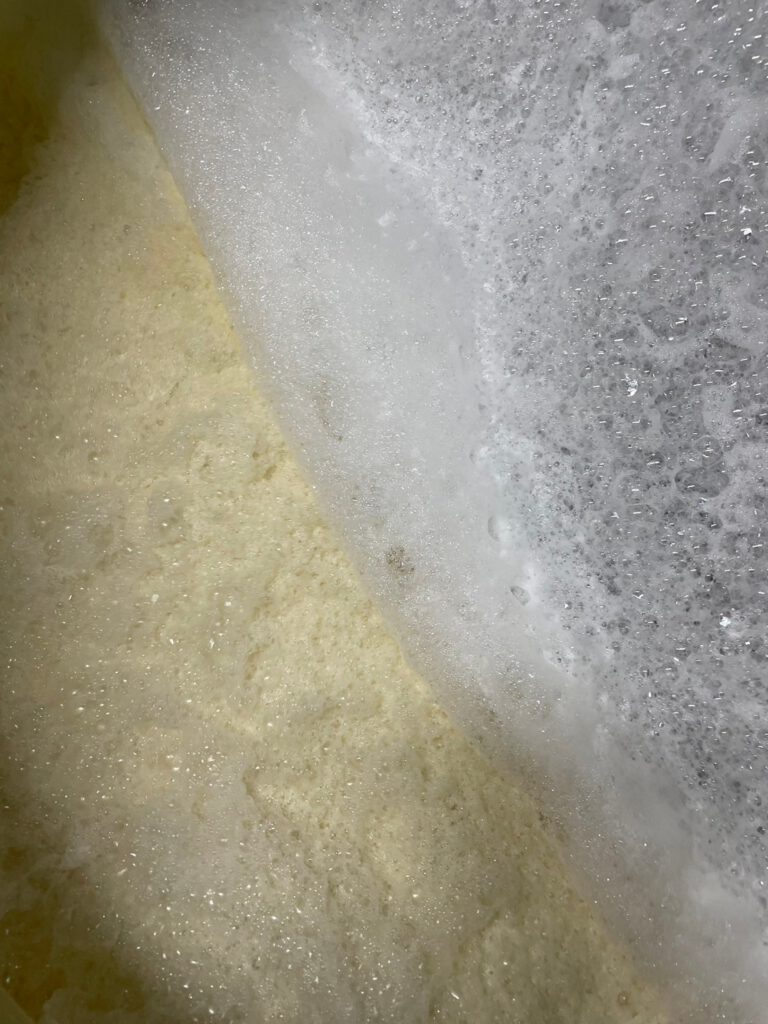

Fouling occurs when contaminants like organic matter, bacteria, or suspended solids accumulate on membranes.

Scaling results from the precipitation of minerals such as calcium carbonate, magnesium sulfate, or silica in feedwater

Impact

Reduced ion exchange efficiency. Decreased flow rate and increased pressure drop. Poor water quality and higher energy consumption.

Repair Solutions

Chemical Cleaning : Specialized cleaning agents remove fouling and scaling without damaging membranes or resins.

Membrane Replacement : Severely fouled membranes are replaced to restore functionality.

Feedwater Pretreatment: Installing or optimizing pretreatment systems, like reverse osmosis (RO), minimizes fouling and scaling in the future.

- Resin Loss or Degradation

Resin can degrade over time due to chemical exposure, improper feedwater quality, or physical stress.

Loss of resin occurs when internal components fail, allowing resin particles to escape.

Impact

Reduced ion exchange capacity, leading to poor water quality. Imbalance in resistivity levels, making the system inefficient.

Repair Solutions

Resin Replacement : Replacing degraded resin with high-quality ion exchange resin.

Component Inspection: Checking for and repairing damaged internal components to prevent future resin loss.

System Calibration : Ensuring correct operational settings to prolong resin life.

- Electrical Failures

Voltage and current imbalances caused by damaged electrodes or control system faults.

Excessive heat generation leading to burnt components.

Impact

Disruption of ion migration, significantly reducing deionization efficiency.

Increased system downtime and operational costs.

Repair Solutions

Electrode Replacement : Repairing or replacing burnt or damaged electrodes. Electrical System Calibration: Adjusting voltage and current settings to match manufacturer specifications. Regular Maintenance: Conducting periodic electrical inspections to detect and resolve issues early.

- Mechanical Damage

Physical stress during operation, improper handling during maintenance, or manufacturing defects.

Damage to membranes, seals, or stack housing.

Impact

Leakage, reduced structural integrity, and compromised system performance.

Repair Solutions

Component Repair or Replacement: Damaged parts such as membranes, seals, or housing are replaced to restore the stack’s structural integrity. Enhanced Handling Practices: Training maintenance teams to handle EDI stacks with care.

- Poor Operational Practices

Incorrect operational parameters such as excessive flow rate, pressure, or temperature.

Insufficient monitoring of performance indicators.

Impact

Accelerated wear and tear of system components. Inefficient operation and inconsistent water quality.

Repair Solutions

System Audit and Optimization: Adjusting operational settings based on system specifications.

Real-Time Monitoring: Implementing automated monitoring systems for key parameters such as resistivity, flow rate, and pressure.

Preventive Measures

to reduce the likelihood of EDI stack failures, it is essential to adopt preventive measures:

Regular Maintenance : Routine inspections and servicing to detect and address issues early.

Feedwater Quality Management : Installing advanced pretreatment systems to ensure feedwater meets EDI specifications.

Performance Monitoring : Using IoT-based systems to track parameters in real time and identify potential issues.

Conclusion

Failures in EDI stacks can significantly impact operational efficiency and water quality. However, with proper diagnostics, professional repairs, and preventive strategies, these issues can be resolved efficiently. Repairing EDI stacks instead of replacing them not only reduces costs but also supports sustainability goals by minimizing waste.

Partnering with experienced professionals for EDI repair and maintenance ensures long-term reliability and performance of your water treatment system.

GET IN TOUCH

0 Comments